For energy conservation, noise reduction, low fluid resistance, rapid on-off, axial flow check valve has been widely used for oil and gas transmission pipeline. In China, for large LNG terminals having been built or under construction, axial flow check valve is installed at the position where non-return is required. During design, advancement, reliability, safety and stability of technology should be taken into consideration. What’s more, damping, shock absorption and energy conservation should be followed. For this, axial flow check valve came out.

LNG terminal is mainly used to receive LNG transported by LNG ship. Then, it transmits LNG to downstream users through gas transmission pipeline or lorry. The whole system includes discharge, storage, vapor processing, LNG pressing and gasification, gas transportation and measurement, gas system, lorry, emission and safety relief. According to requirements of technology, all of systems in LNG terminal should be equipped with axial flow check valve in case of backflow. However, most of check valves depend on import and have high price. So, only a few of key positions are equipped with the valve.

1. Water hammer

Water hammer means that sharp variation of fluid flow velocity in pipes results in fluid pressure changing obviously, repeatedly and rapidly. Tube wall is stressed and causes noise due to pressure impact, just like hammer hitting tube, called as water hammer. The main damage of water hammer is that pressure variation in pipe makes tube and equipment vibrate sharply. Stress on tube exceeds normal range, destructing pipe and relevant facilities and easily causing leakage or fire.

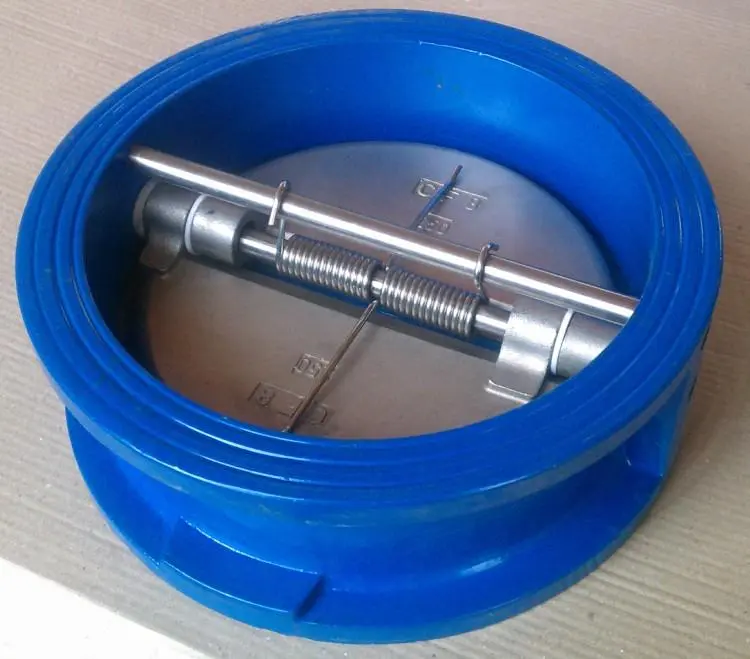

Axial flow check valve opens or closes quickly. The disc has short stroke and does not hit body or seat when spring resets. So, the valve can reduce water hammer efficiently.

2. Batch operation

In general, LNG terminal is designed for continuous operation all the year round. The terminal should meet the requirements of urban continuous gas supply except for irresistible incidents. But, based on different function of systems and market conditions, some systems are not continuous during operation. Valve in batch operation may close or open suddenly, easily making subsequent fluid cause water hammer under inertia. So, when choosing check valves for LNG terminal, axial flow check valve should be used for batch operation.

3. Higher fluid pressure

The higher fluid pressure is, the higher instant differential pressure is when the valve opens or closed suddenly. The higher pressure in pipe is, the higher fluid inertia is when valve closes suddenly and the higher damage on pipe caused by fluid shock wave is. So, when choosing check valves for LNG terminal, axial flow check valve should be adopted in terms of high fluid pressure.