In the actual operation of steam turbines, the pressure relief valve is generally prone to jamming. When the unit impulse reaches the rated speed and exits the high-pressure start oil pump, the pressure relief valve of the main oil pump inlet is prone to jamming, which makes the main oil pump inlet's oil pressure low and tripping occurs for the unit due to protection.

1. Several possibilities leading to low oil pressure at the main oil pump inlet

(1) Whether the nozzle strainer of the low-pressure injector is blocked; whether or not the pad is in a good condition.

(2) Whether the check valve at the outlet of the main oil pump is jammed, and whether the check valve at the outlet of the high-pressure start oil pump is jammed.

(3) Check whether the oil drain valve at the inlet of the main oil pump is jammed.

(4) The poor quality of the turbine oil causes the slide valve to jam and the filter screen is blocked.

2. Analysis of the tripping of the unit caused by jamming of the pressure relief valve and the drop of oil pressure

(1) Failures

Generally, when the unit impulse reaches 3000RPM and exits the high-pressure start oil pump, jamming of the pressure relief valve occurs instantly. In the long-term operation, the main oil pump inlet oil pressure gradually decreases, resulting in a breakdown. It is generally caused by the failure of the low-pressure injector, resulting in a decrease in the oil volume of the main oil pump inlet.

(2) Specific analysis of low oil pressure at the inlet of the main oil pump due to jamming of the oil drain valve

When the unit has reached 3000RPM and the high-pressure start of the oil pump is stopped, the outlet oil pressure of the main oil pump drops, which causes the unit to trip. After checking the low-pressure injector and the oil level of the oil tank, there is no problem with them. The drain valve should be well checked. The drain valve is located between the oil pump inlet pipe and the oil tank return pipe, and the oil drain valve drains the oil in the main oil pump inlet oil pipe. The signal of the oil drain valve is the oil pressure at the outlet of the high-pressure start oil pump, which is an oil pipe with a diameter of Φ18 mm.

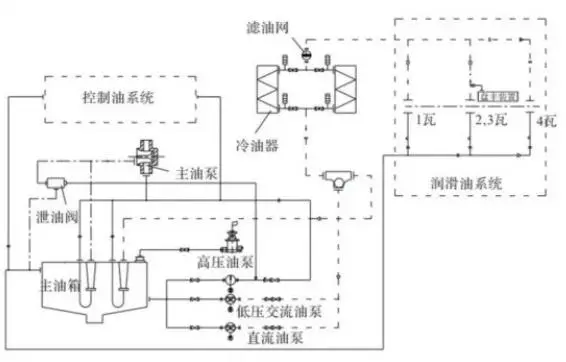

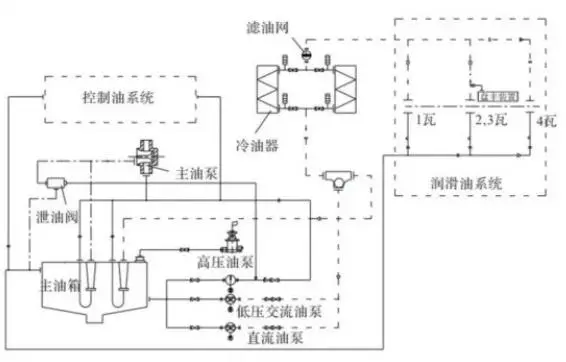

The oil circuit of the outside of the steam turbine

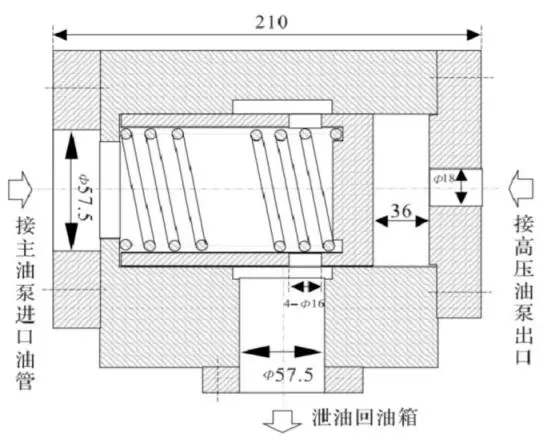

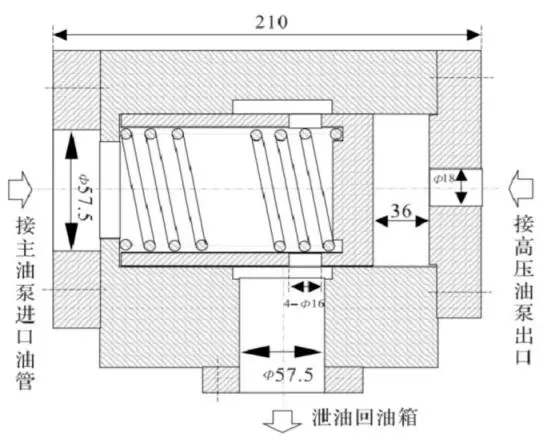

The structure of the drain valve

The working principles and troubleshooting of the drain valve

One end of the drain valve is connected to the outlet of the high-pressure start oil pump; another end is connected to the oil return pipe, and the other end is connected to the inlet pipe of the main oil pump.

⑴ When the unit is working, the high-pressure start oil pump runs. At this time, the unit's regulating and security lubrication system is provided by the high-pressure start oil pump. The pressure of the high-pressure oil through the pressure signal oil pipe overcomes the oil pressure of the slide valve spring force and the main oil pump inlet, so that the slide valve of the oil drain valve moves to the left, and then opens four oil drain holes with a diameter of Φ16 mm, making the main oil pump's inlet pipeline drain oil. The main oil pump does not participate in this part of this process.

⑵ When 3000RPM is reached for the unit, the high-pressure start of the oil pump is stopped. The oil pressure in the high-pressure oil signal oil pipe disappears, and the drain valve moves to the right to close four holes with a diameter of Φ16 mm and stops draining the oil, making sure that the main oil pump inlet will not run out of oil. From this moment, the main oil pump participates in the work to supply oil to the adjustment security and lubrication system of the unit.

⑶ In the case of the slide valve of the drain valve being jammed, the moment when the high-pressure start of the oil pump is stopped at 3000RPM, the main oil pump's inlet oil pressure does not close the drain hole due to the jamming of the oil drain valve, which makes the main oil pump inlet short of oil. The inlet oil pressure of the main oil pump decreases, and the outlet oil pressure decreases. When the outlet oil pressure is lower than 0.78MPa, the unit will trip and the high-pressure start oil pump will automatically start due to the protection of the oil pressure. At the moment of stopping the oil pump, the steam turbine trips from 3000RPM, and the speed drops.

⑷ Disassemble and clean the slide valve of the drain valve, cavity and spring with diesel oil to ensure that the slide valve moves flexibly. Reinstall it, and start the steam turbine. Stop the high-pressure oil pump, and verify that the drain valve can be closed normally. The oil pressure at the inlet and outlet of the main oil pump is normal; the oil pressure of the safety pulse system is normal, and the grid is connected with loads.

3. Solutions to the tripping due to low inlet pressure of the main oil pump

When the steam turbine rushes to 3000RPM and exits the high-pressure start oil pump, the main oil pump's inlet pressure is low, that is, the main oil pump inlet is short of oil, and the unit trips. The root cause is that the pressure relief valve's slide valve on the main oil pump inlet pipe is jammed and the oil drain hole is not able to shut down, causing the main oil pump inlet oil pressure to be low. The unit trips due to protection. If the unit is stopped, the pressure relief valve can be disassembled. Clean the internal impurities, and the surface of the slide valve should be ground to make it flexible and reliable. If the unit is not stopped, use the method of increasing the speed of the unit to make the internal slide valve of the pressure relief valve overcome resistance of jamming and close the drain hole, ensuring reliable oil pressure at the main oil pump inlet and exiting the high-pressure start oil pump normally.

Specific operational processes and technical principles

⑴ After the unit reaches 3000RPM, make the high-pressure oil pump run to the speed of 3180RPM. 3180RPM is the upper limit of the unit actuator. As the unit speed increases, the main oil pump outlet oil pressure also increases. At this time, the main oil pump outlet oil pressure is higher than the oil supply pressure of the high-pressure starting oil pump. The main oil pump outlet check valve is opened under the action of the pressure difference. The main oil pump of the steam turbine starts to supply oil, and the main oil pump is put into operation. One side of the main oil pump outlet supplies the low-pressure injector inlet, and the low-pressure injector outlet supplies oil to the main oil pump inlet.

⑵ Before the unit reaches 3000RPM, it is supplied by the high-pressure starting oil pump and the oil pressure generated by pressure signal oil circuit with Φ18 mm at the outlet of the high-pressure starting oil pump is greater than the spring force in the drain valve and oil pressure the main oil pump inlet, that is, the pressure signal's oil pressure is greater than the spring force and main oil pump inlet oil pressure; the slide valve moves to the left, and 4 oil drain holes are opened; the oil in the main oil pump inlet pipe is drained. At this time, the unit speed is 3180RPM. The main oil pump outlet's oil pressure is higher than 3000RPM, and the main oil pump inlet's oil pressure also increases. The main oil pump inlet's oil pressure plus spring force is greater than pressure signal oil's pressure; the slide valve overcomes the resistance of jamming due to impurities, moves to the right and closes the four oil drain holes to ensure that the main oil pump inlet is not short of oil. The main oil pump starts to supply oil, and the high-pressure start oil pump has exited from the oil supply. Manually stop the high-pressure start oil pump, the unit will not trip. The unit's speed is gradually reduced to 3000RPM, and connects to the grid with loads.