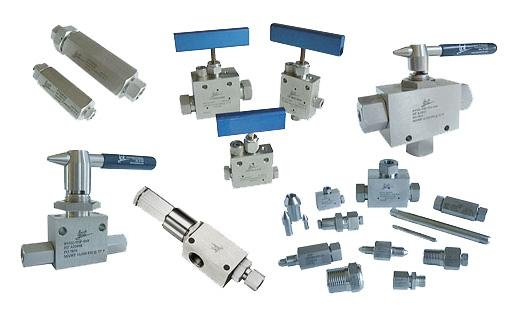

Nowadays, superhigh pressure technique has already been used for petrochemical industry, chemical industry, metal forming, powder metallurgy and other industries. Due to superhigh pressure technique widely applied, the performances of

superhigh pressure valve have directly influenced on security, reliability, operating efficiency and service life of the whole superhigh pressure system.

The main reasons causing superhigher pressure valve losing efficacy are cavitation and erosion. There are various factors impacting cavitation and erosion, mainly including mechanical properties of materials, hydrodynamic factors and environmental influence.

To improve erosion resistance of superhigh pressure valve, the materials should have the following properties:

1. Having high hardness;

2. Having high fatigue strength;

3. Having yield strength and good stability;

4. Containing protective film which has acid corrosion resistance.

To extend service life of superhigh pressure valve, the following conditions should also be considered:

1. When install or change valve, the valve should be cleaned appropriately, in case of sundries which may accelerate valve abrasion.

2. The valve cannot operate under high temperature. Temperature of media has high impact on service life of valve. The higher temperature of media is, the shorter service life of valve is.

3. Filter high temperature media and clean filtrator on time. When add fluids, the fluids should be filtered by filtrator. If the valve operates frequently, maintenance period should be reduced appropriately. Clean fuel tank on time, meanwhile change new media.

4. Under different pressure, use relevant pressure sealing pressure and choose suitable sealing specific pressure.